Bosnia and Herzegovina was one of the most polluted parts of the former Yugoslavia and was responsible for 32% of its total air pollution. The biggest polluter was industry including the steel factories in Zenica, Ilijaš and Vareš, thermal power plants in Kakanj, Tuzla, Ugljevik and Gacko, chemical and coke plant in Lukavac, and also the cement factories in Kakanj and Lukavac.

Cement production is a part of technological pollution where the most polluting substances are solid particles or dust reported as PM10. Emission of dust is regulated easier than emission of gases from technological facilities. Nevertheless industrial waste from both cement factories in Kakanj and Lukavac belong to the most significant pollutants in the country.

Owing to the lack of comprehensive information, the air quality in the country's cities and regions is largely unknown, while the overall air quality is better now than before the war, due to reduced industrial activities. It is feared that poor air quality still prevails at the local level and in particular in several cities. The Meteorological Institute has identified at least nine hot spots, one of them is the Kakanj area, affecting 1.3 million inhabitants, which is about one third of the total population.

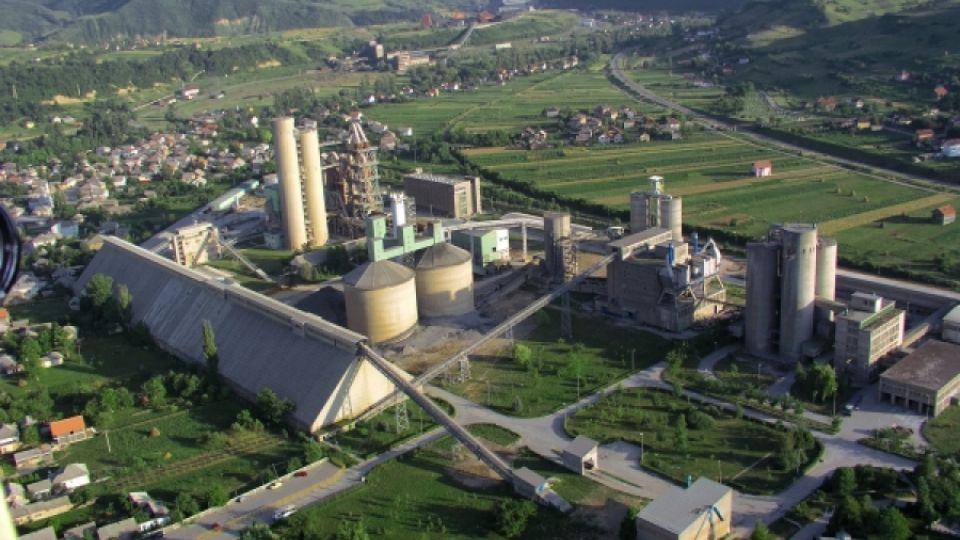

The Kakanj cement factory was built in the vicinity of the thermal power plant. Problems with dust emissions are said to be related more to the management process than the equipment.

Technical state of the factory

The plant has been inoperative since May 1992 because of the war. During the war, the demand for cement was limited and has been supplied from residual stocks or trucked from Split in Croatia. Once a peace agreement has been reached, the demand for cement started to be enormous as war damage was extensive.

Recent upturn

Cement factory Kakanj was founded in 1978 and privatized in July 2000. A majority was bought by the German group HeidelbergCement, one of the largest manufacturers of building materials in the world, with about 44,900 employees. The world's giant pledged to the Kakanj cement plant to invest 95.95 million KM. The production technology started to improve from year to year and it now reaches the standards of environmental protection at European level. In 2013, the record production of 203.000 mᶟ of cement was achieved.